Cement is an important construction ingredient around the world, and as a result, cement production is a significant source of global carbon dioxide (CO2) emissions, making up approximately seven percent of annual greenhouse gas emissions in large part through the burning of quarried limestone.

Now, a research team at the University of Colorado Boulder has claimed to have figured out a way to make cement production carbon neutral – and even carbon negative – by pulling carbon dioxide out of the air with the help of microalgae.

Limestone is a key ingredient in cement, but adding it to the mix is incredibly energy-intensive. It is extracted from large quarries and burned at high temperatures, releasing large amounts of carbon dioxide. The research team found that replacing quarried limestone with biologically grown limestone, a natural process that some species of calcareous microalgae complete through photosynthesis, creates a net carbon-neutral way to make cement.

Material Scientist Wil Srubar, a lead principal investigator on the project, received a National Science Foundation CAREER award in 2020 to explore how to grow limestone particles using microalgae to produce concrete with positive environmental benefits. The idea came to him while snorkeling on his honeymoon in Thailand in 2017. He saw firsthand in coral reels how nature grows its own durable, long-lasting structures from calcium carbonate, a main component of limestone.

He and his team began to cultivate coccolithophores, cloudy white microalgae that naturally sequester and store carbon dioxide in mineral form through photosynthesis. With only sunlight, seawater, and dissolved carbon dioxide, these tiny organisms produce the largest amounts of new calcium carbonate on the planet and at a faster pace than coral reefs. Coccolithophore blooms in the world’s oceans are so big that they can be seen from space. These microalgae live in both warm and cold, salt and fresh waters around the world, making them great candidates for cultivation almost anywhere.

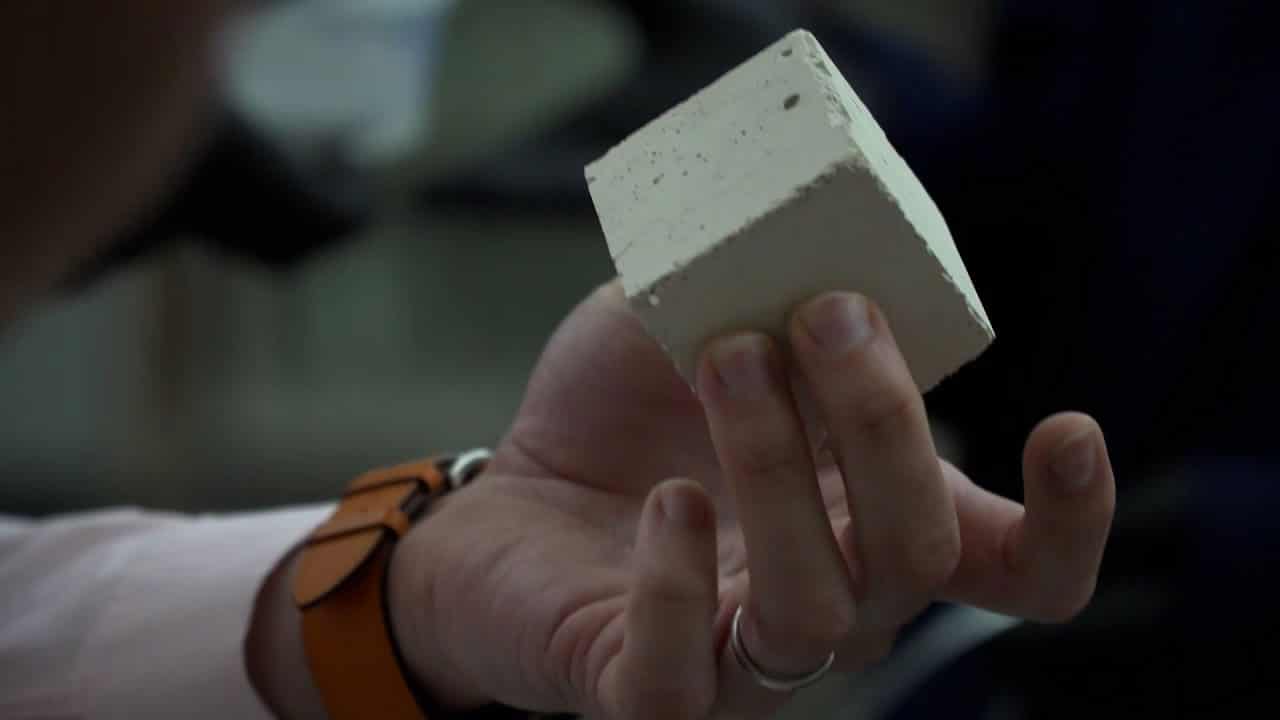

“On the surface, they create these very intricate, beautiful calcium carbonate shells. It’s basically an armor of limestone that surrounds the cells,” said Subaru.

Researchers used coccolithophores to produce biogenic limestone-based cement with a far lower environmental footprint. “This is a really exciting moment for our team,” said Subaru. “For the industry, now is the time to solve this very wicked problem. We believe that we have one of the best solutions, if not the best solution, for the cement and concrete industry to address its carbon problem.”

The research team has been rewarded for their innovative work with a $3.2 million grant from the U.S. Department of Energy (DOE) to develop and scale up the manufacture of biogenic limestone-based cement.

Limestone isn’t the only product microalgae can create – microalgae’s lipids, proteins, sugars, and carbohydrates can be used to produce biofuels, food, and cosmetics, meaning these microalgae could also be a source of other, more expensive co-products – helping to offset the costs of limestone production.

“We make more concrete than any other material on the planet, and that means it touches everybody’s life,” said Subaru. “It’s really important for us to remember that this material must be affordable and easy to produce, and the benefits must be shared on a global scale.”

Biogenic limestone-based cement promises carbon-zero buildings

Source: Global Access News

No comments:

Post a Comment